Therefore, Intel has bet on its upcoming 18A node. Meanwhile, the company doubled down on what it said was a very aggressive existing roadmap by revealing plans for one new 10A or 1nm process in 2027. But here's the thing. In terms of products you can actually buy, Intel has accomplished shockingly little since Pat Gelsinger arrived and subsequently launched the so-called “IDM 2.0” master plan.

To recap: IDM 2.0 was the new strategy that Intel introduced almost three years ago. The IDM bit describes the Integrated Device Manager and the high-level ideas that involved reasserting its leadership in chip design and manufacturing and then carving out an additional role as a major chip foundry services provider for Third parties, including competitors such as AMD and Nvidia, to develop .

A large part of this master plan, which on the surface seemed like an incredibly ambitious, self-imposed roadmap, included no fewer than five new chip production nodes to be launched within four years, according to Intel, culminating in that all-important 18A process. Intel predicted that this would return the company to the forefront of advanced chip technology, overtaking TSMC in the process.

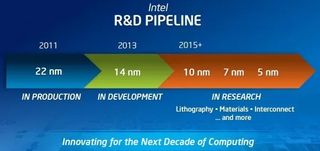

On closer inspection, one could argue that Intel's plan actually amounts to far fewer than five nodes. Officially, the new nodes are Intel 7, Intel 4, Intel 3, Intel 20A and Intel 18A.

A cynic might argue that Intel 7 is actually just a rebrand and optimization of its existing and problematic 10nm node, Intel 3 is derived from Intel 4, and the same goes for Intel 18A in relation to Intel 20A. In this case, at the time of announcing the new roadmap, Intel has actually only committed to two completely new nodes, Intel 4 and Intel 20A.

However, given Intel's frankly terrible track record with new silicon nodes of late, it was still very ambitious. Back in 2012, Intel planned to launch 10nm CPUs as early as 2015. In fact, it wasn't until September 2019 that the company managed to bring a truly commercial 10nm product to market with Ice Lake. It then took over four years before it barely managed to release a CPU on the next all-new node, Intel 4, when its latest mobile Meteor Lake chips hit the market just weeks before 2023.

And remember, Meteor Lake only contains a tiny strip of Intel 4 silicon. Most of the chiplets that make up a Meteor Lake CPU are manufactured by TSMC, not Intel. Only the actual computing tile is an Intel 4 chip. So you could say that all Intel has accomplished since the Gelsinger takeover, at least in terms of the chips you can buy, is to drop a tiny amount of Meteor Lake CPUs on that Intel 4 node .

There were certainly other CPU launches, including the Alder Lake and Raptor Lake families. But these didn't bring Intel any closer to implementing this mission-critical roadmap. And here we are in 2024 and Intel has until the end of next year to implement the whole thing.

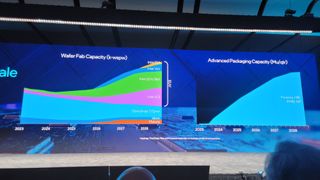

All of this raises the question of what exactly is going on at Intel. Some answers were provided at the recent Intel Foundry Direct Connect event. Intel showed a graphic depicting its planned chip production capacity through 2029.

What came out of it was actually a little shocking. According to Intel's plans, the company's total chip production capacity will shrink slightly in 2023 and 2024 and will not exceed the 2023 level until 2027.

Furthermore, the same graph shows that even in 2025, those produced on the Intel 4 and 3 nodes (which the company usefully groups together for this performance measurement, although it characterizes them as distinct nodes in its PR-friendly roadmap) are a small minority and will, strangely enough, have already been slightly overtaken by the 20A/18A node (again, bracketed together because they are actually two versions of essentially the same node).

However, real success will only come in the second half of the decade. That means Intel still has an awfully long way to go.

Capacity for both the Intel 4/3 and 20A/18A nodes will increase slightly in 2026, but it's not until 2027 that Intel itself expects to release a decent amount of chips on these new nodes. That's not quite what you might have expected when Intel announced this bold roadmap redesign in 2021, is it? Five new nodes in four years, except that it's only two nodes and we won't be making anything with them in large quantities for six years might have been more accurate.

Anyway, the wafer capacity data released by Intel helps to understand the fact that Intel plans to use TSMC to support its CPU manufacturing in the coming years. It takes at least 2026 – and Really only in 2027 – that it will have enough internal capacity to produce large quantities of CPUs on its newest nodes.

The graphic also makes sense of rumors that even the CPU chip in the upcoming Arrow Lake desktop CPUs will be mostly manufactured at TSMC. Arrow Lake is known to be Intel's first consumer product to use its new 20A node for the CPU chip, while the other chiplets in the CPU package such as the IO chip and graphics chip will be manufactured by TSMC.

However, rumors are circulating that most models within the Arrow Lake CPU stack will feature TSMC silicon for all chiplets including the CPU dies. As the story goes, only a few models with a certain core count will receive Intel 20A silicon. When you look at how long it will take Intel to increase its 20A capacity according to the roadmap, these rumors suddenly make a lot of sense.

In this context, the idea that Intel is planning “10A” silicon for 2027 seems a bit absurd. With Intel 4/3 and 20A/18A things are just getting started. And we haven't even mentioned the new 14A node yet.

So when you add it all up, Intel's bold roadmap wasn't all that bold. Maybe Intel will release a few Arrow Lake models this year that contain a tiny piece of 20A silicon. Gelsinger can therefore claim that everything is on the right track. But it will be a fairly cosmetic achievement. What's frustrating is that real success won't come until the second half of the decade. That means Intel still has an awfully long way to go.